TAILOR MADE VALVES

From time to time, site related problems involving valves are brought to us by clients. While for most, the client himself has the solution and IVC's opinion is sought for reinforcement only, there are some that involves a fair bit of research, some R&D exercises and temper the effort with IVC’s repertoire of rich experience spanning more than 50 years.

Bhandup pumping station (Mumbai) - IVC Butterfly valve since 1982

For instance when pump delivery side gate valves, 1200 NB, burst like clay at Bhandup pumping station in Mumbai (1978), eminent engineers from Binny and Partners, Tata Consulting engineers and the Municipal Corporation decided to replace all delivery side gate valve with Butterfly valves, still new for users in India. It was IVC that took up the challenge. All the valves were to operate under ‘Free discharge condition’, necessitating the use of large gear box, thicker shaft etc., 16 bar valves in DI construction were designed and manufactured at IVC’s Nasik plant, the valves commissioned in 1981-82. These valves are still working.

Trombay (Mumbai) - Anti Vacuum valves during 1991-1992

The time when pipe burst near Trombay (Mumbai) literally flooded the township. These are 3 or 3.6 mtr dia. Mains. We designed and supplied 15” dia. 6 nos Anti Vacuum valves during 91-92. These prevented vacuum formation within every time there was a pump trip due to grid failure, there have been no such pipe burst since, 28 years that is.

There are many such instances where IVC has gone the extra mile and delivered solutions that are lasting. Some new valves in the recent few year are :

Air Vacuum Valve

Bringing ‘Ganga-Jal’ to Agra via the twin pipeline(2200 dia.) by gravity might seem easy but due to a very shallow gradient, air pockets within the pipe line could pose serious problems to flow. ‘IVC’ designed and supplied 300 NB air vacuum valves-these valves have the inlet and outlet ports both of 300 mm dia., all St.St. internals and the large buoyant float immensely responsive to differential pressure (air) within and outside the pipeline, capable of suction and discharge of huge quantity of air.

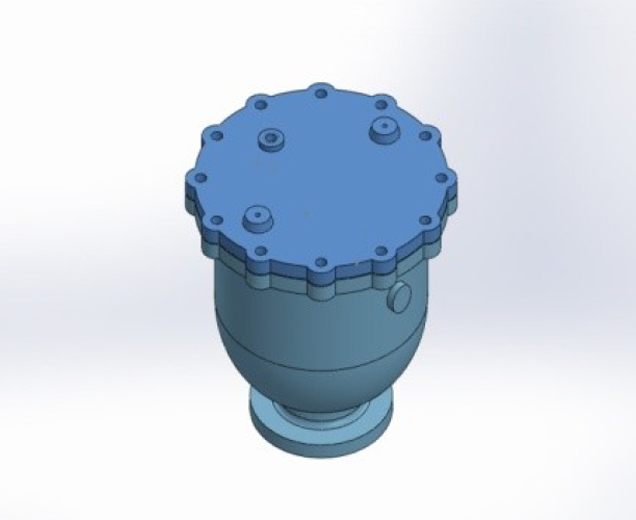

Air Release Valve

Releasing small burst of air at frequent intervals with the pipe line flowing full, the valve is immensely helpful in purging small bursts of accumulated air in the pipe line thereby enhancing discharge capacity of water mains. The float configuration, the lever arrangement and the orifice size is decided upon after careful study of the site condition. By changing the orifice size it can tackle large differential pressures (0.5 to 16 bar).

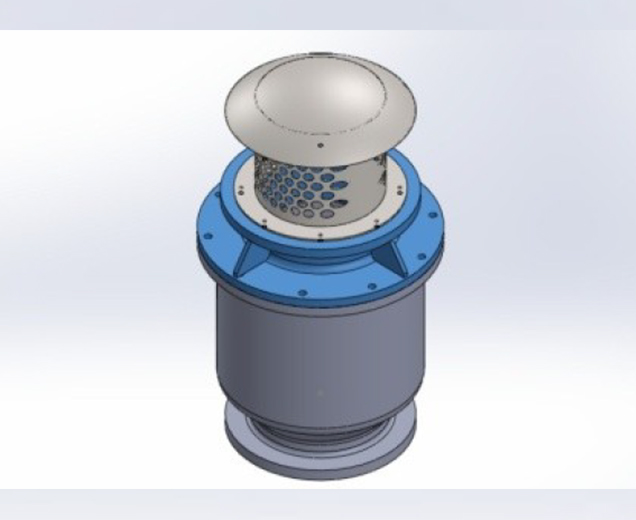

Air Valve for Sewage

The valve is sleek, tall with a coarse mesh within to prevent floating debris from reaching the orifice at the top. With all stainless steel construction, within and without, these valves have found application on sewer mains / pipe lines, where pipelines seldom flow full.

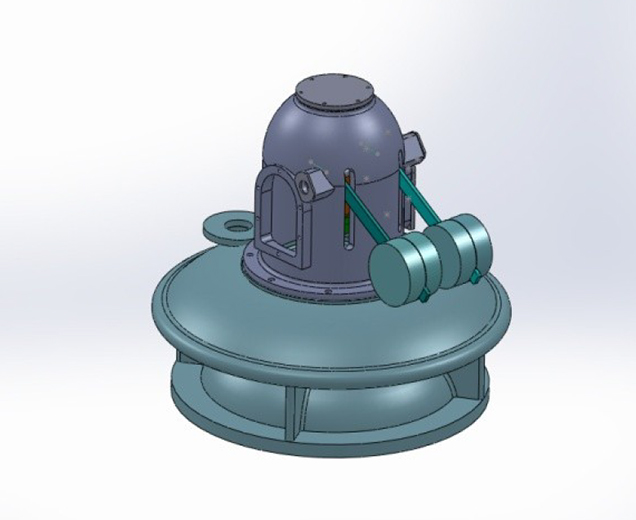

Recoil Check Valve

Designed for arduous duty, in a pumping station with multiple pumps connected, the ‘RECOIL’ (akin to the recoil of a gun) characteristics of door closure without slamming, upon pump trip make this ideal choice for a Non-return valve that can last several decades without maintenance (all metal seat, no elastomer and no oil filled dashpot).

These valves have proven to be a boon for the Hyderabad metro engineers where NRVs (Dual plate, swing check, slanted seat type) were failing with nagging regularity.

Gate Valve with Integral Metal Seats

Apart from its usage in high temperature liquids, application where flow is turbulent and the high velocity dislodges seat and face rings in a gate (Sluice) valve, IVC can design and manufacture valves (single wedge design that is preferred by Japanese Cos.) with Bronze or Stainless steel integral seat and faces that are good for life.

1100 NB (O/R) gate valves supplied to Laos, for a Hydro electric station (dam by pass outlet), is but a recent example.

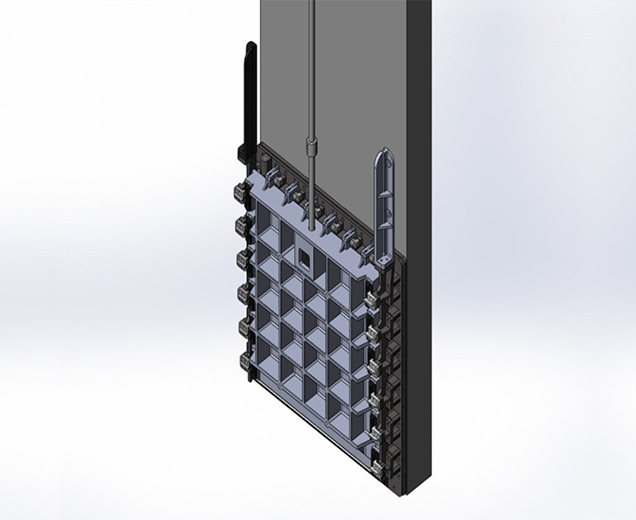

Large Penstocks for High Head application

For heads upto 35 MWC, we have designed and supplied Sluice gates, operated from a platform 30 m above, for some critical installations in the middle east, both electrically operated and operation using servo motor.

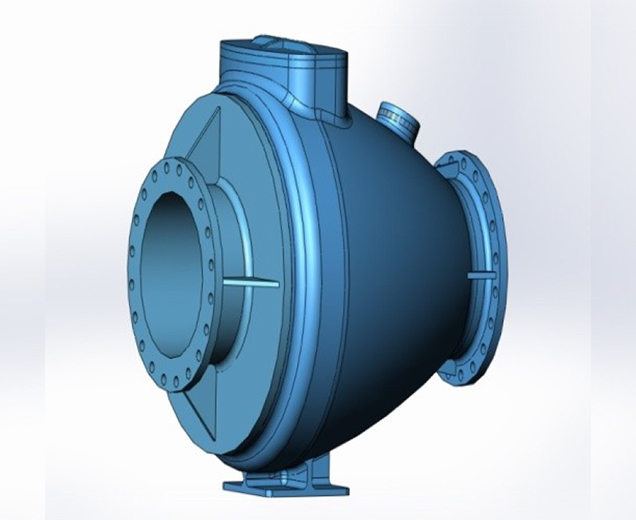

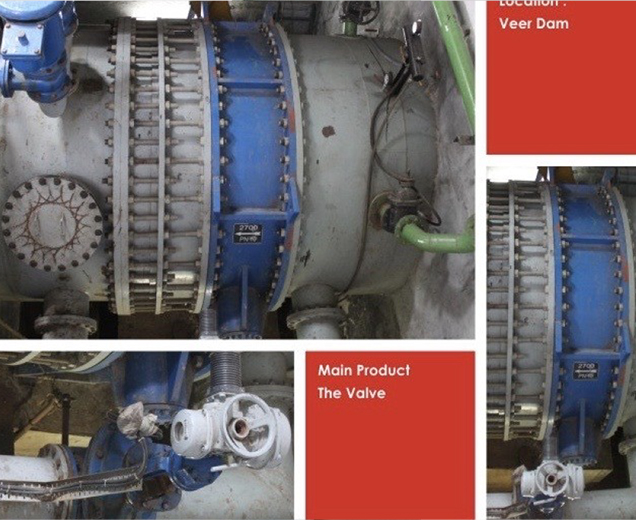

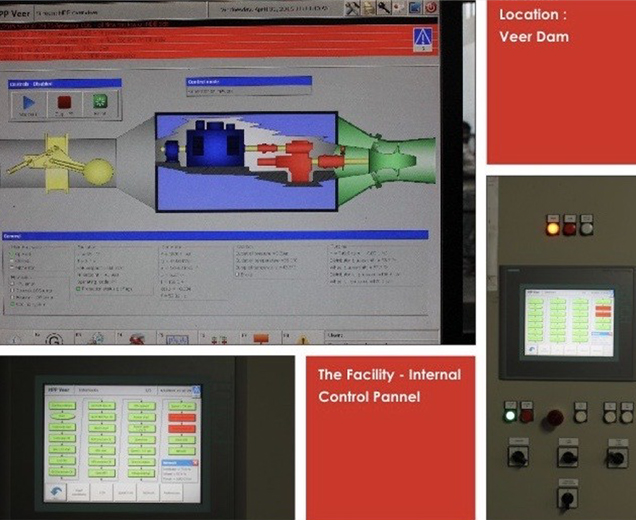

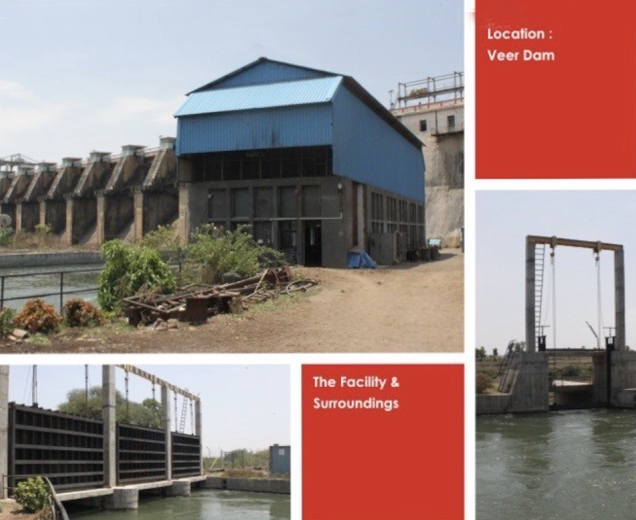

MAIN INLET VALVE FOR HYDRO ELECTRIC TURBINE

2700 NB MAIN INLET VALVE at IVC works

2700 NB MAIN INLET VALVE at IVC works

2700 NB MAIN INLET VALVE at the site.

MAIN INLET VALVE FOR HYDRO ELECTRIC TURBINE

Used mainly for small hydel stations, the valve is servo motor operated with PLC controlls, to close as soon as there is turbine run away.

Conceived and designed in house using 3D modelling and FE analysis, this 2700 mm valve along with accessories has been working in Maharashtra for 10 years now.